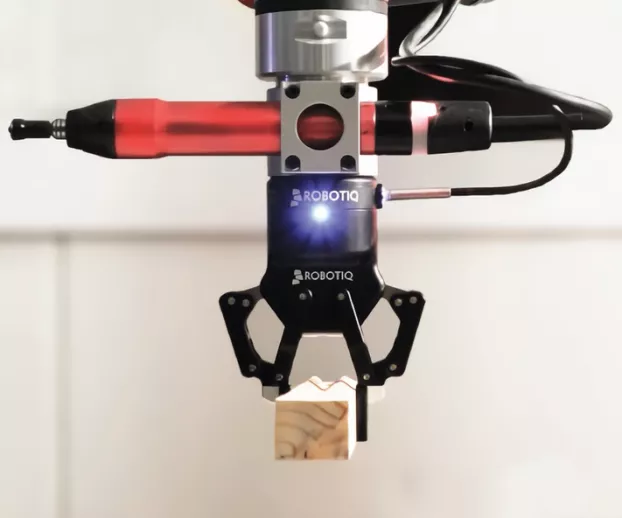

Automated screwdriver solution for collaborative assembly

Utilize robotic solutions to speed up the screwdriving process. Increase throughput and product quality while reducing operating costs by adopting a collaborative solution.

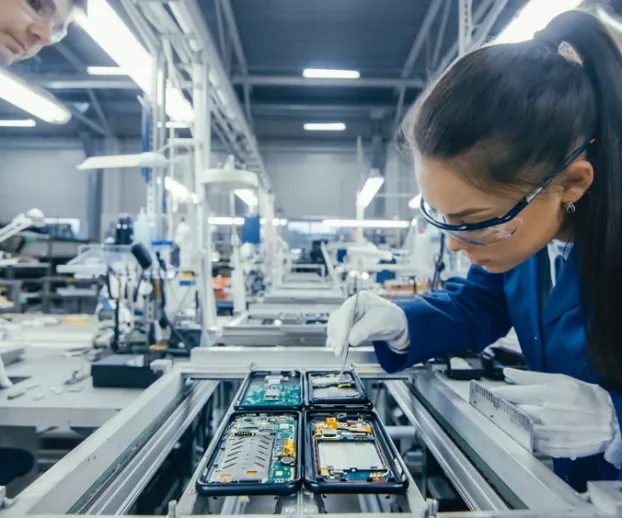

Manual screwdriver challenges

- Inconsistent screwing leads to inferior quality

- High employee turnover and absence rates

- Stable manual operation requires extensive training

- Operations must be standardized to prevent quality claims

- Strict safety regulations must be followed to prevent injury

- Screwdriving is a bottleneck process that slows down the rest of the production

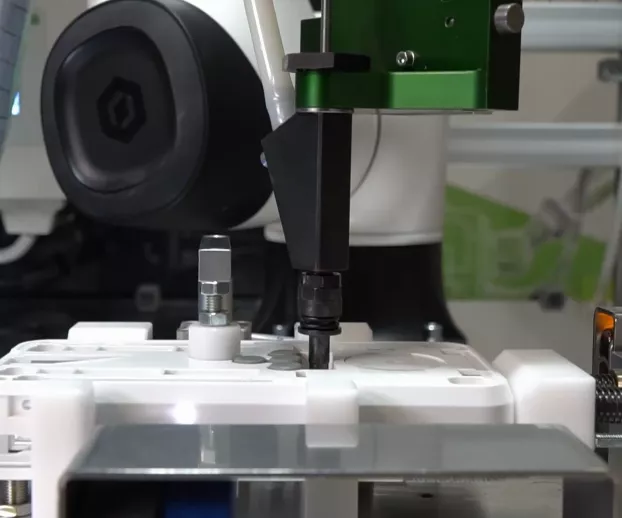

How solution works

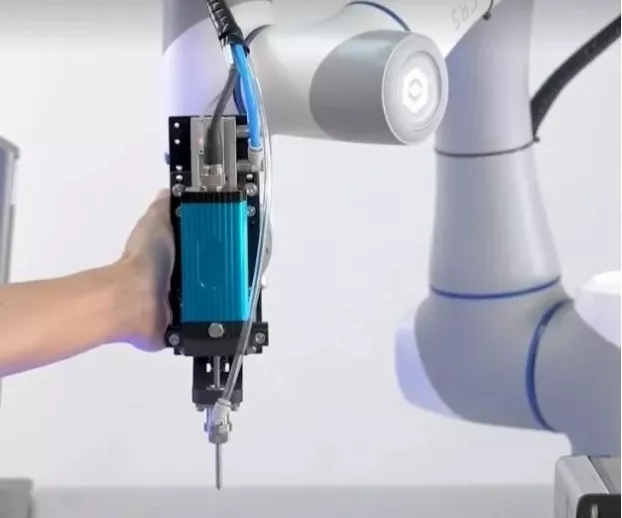

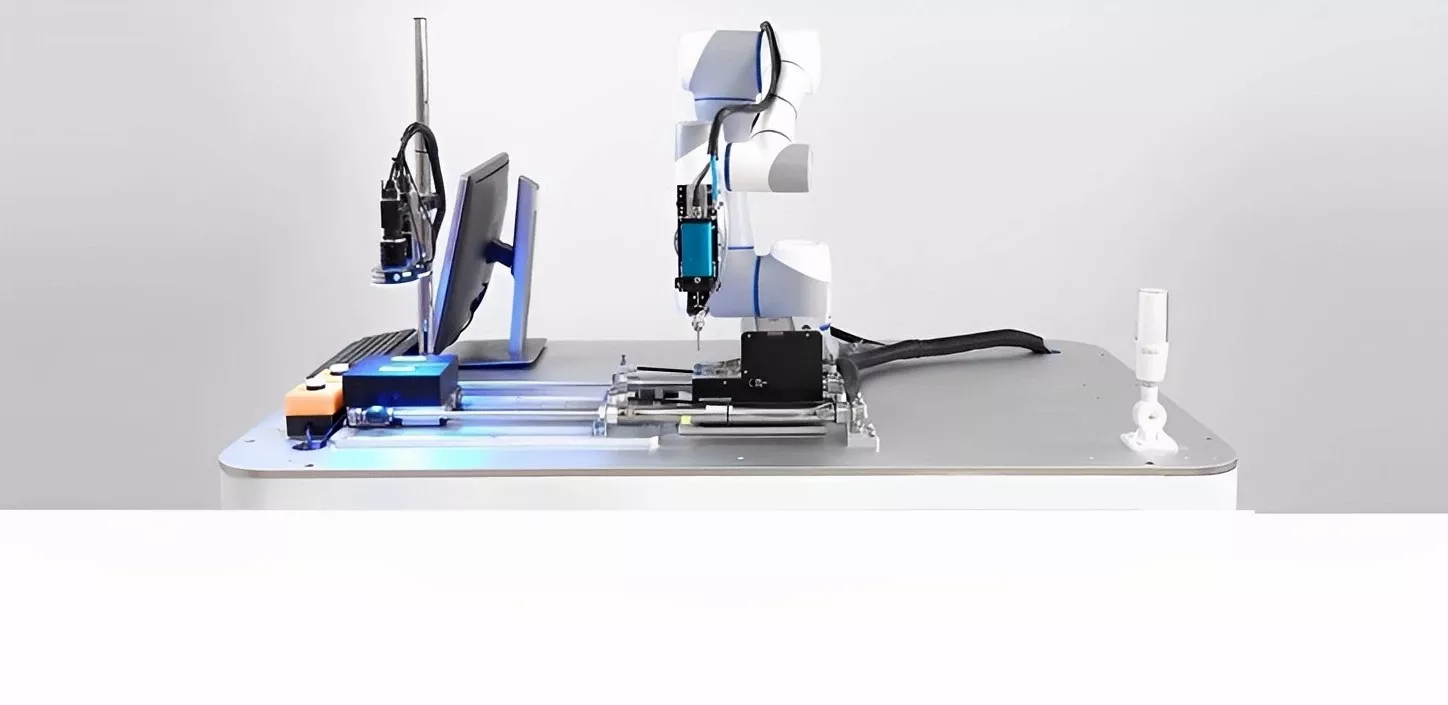

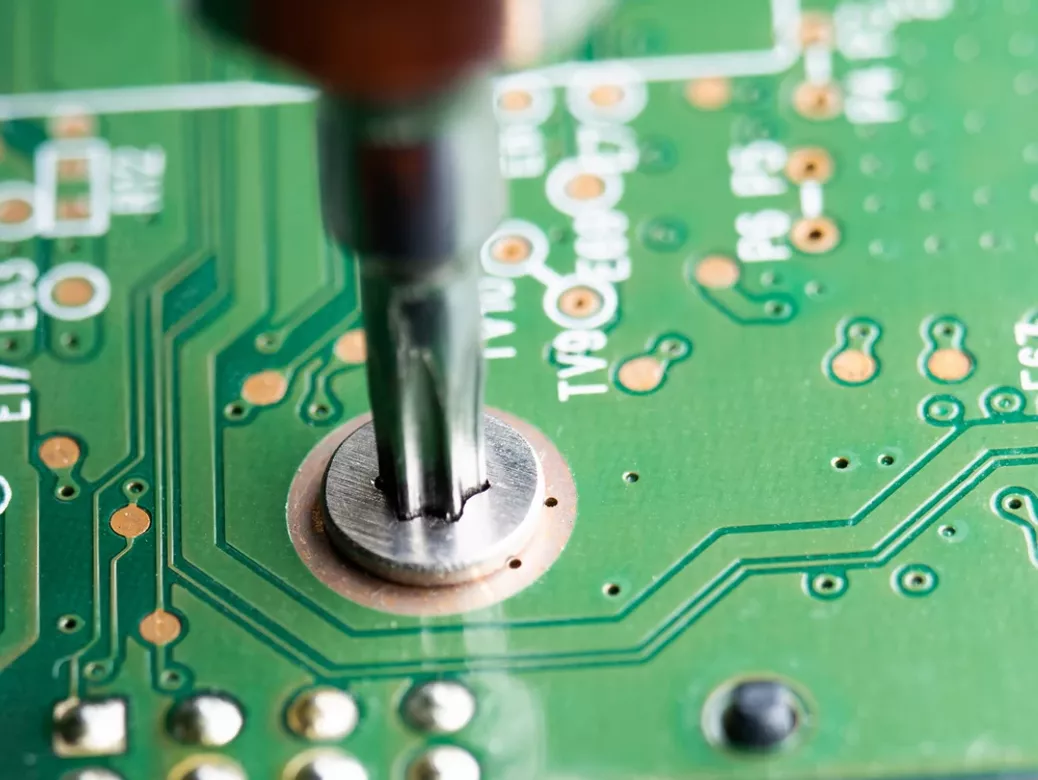

Screwdriving Solution is a robotic tool for fastening components together. A screw feeder dispenses individual screws at a picking zone. Robotic arm with screwing end-effector picks up the screw, positions it appropriately and processes the screwing task autonomously with the precision and necessary torque.

Application scenarios

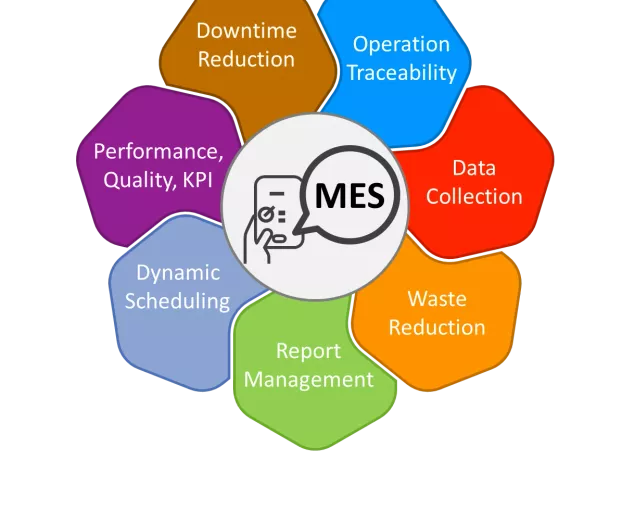

Solution Benefits

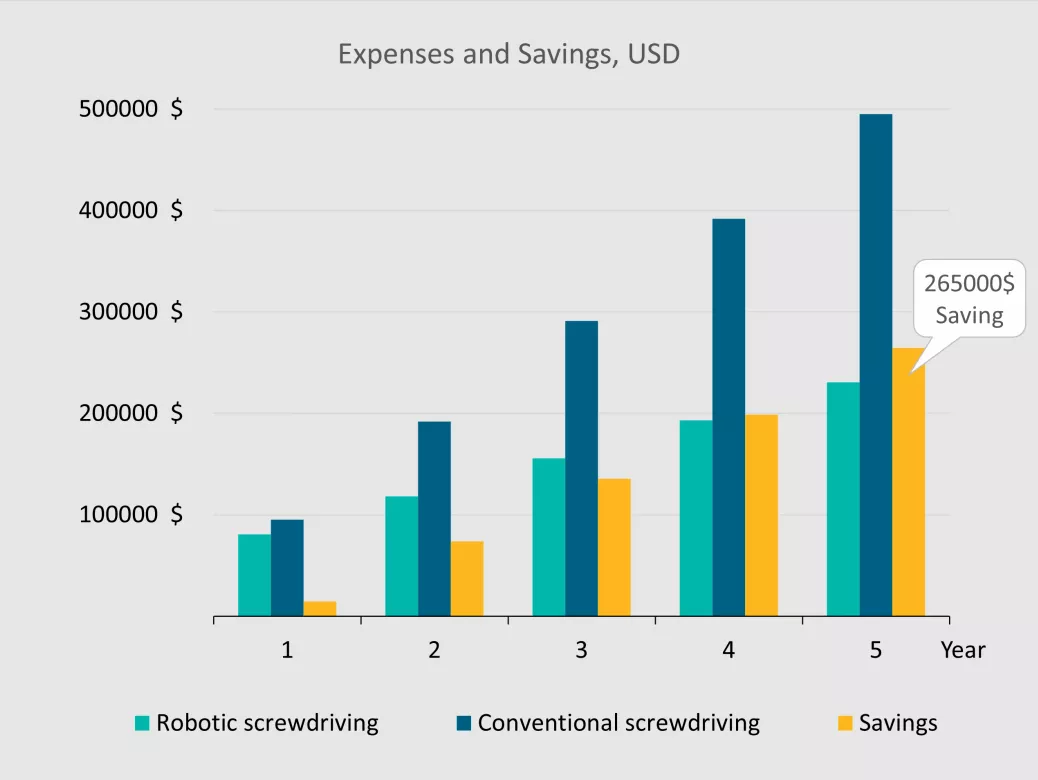

ROI and cost saving

Robotic screwdriving solution operates without breaks. The graph compares the cumulative expenses of robotic screwdriving vs conventional, assuming a 7-day, 3-shift production schedule. ROI 10 months, 5 year savings is $265000.

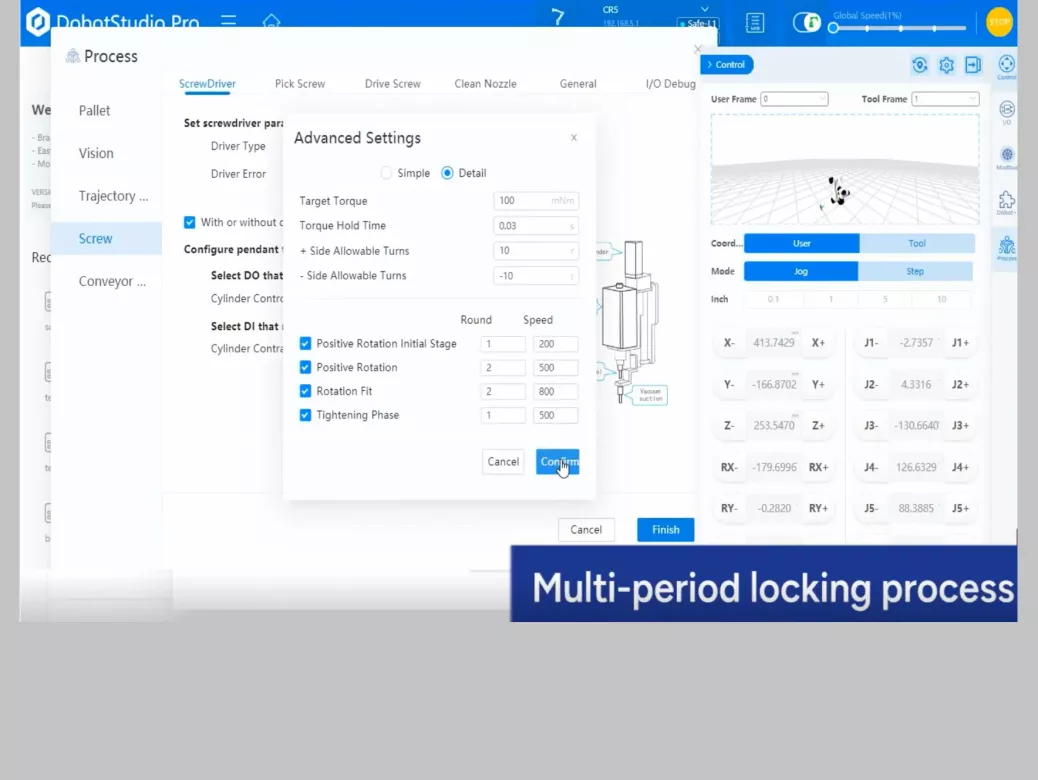

Simple implementation

Without programming knowledge, an operator set appropriate parameters and points. Greatly simplifying the production, the system generates a screwdriving program.

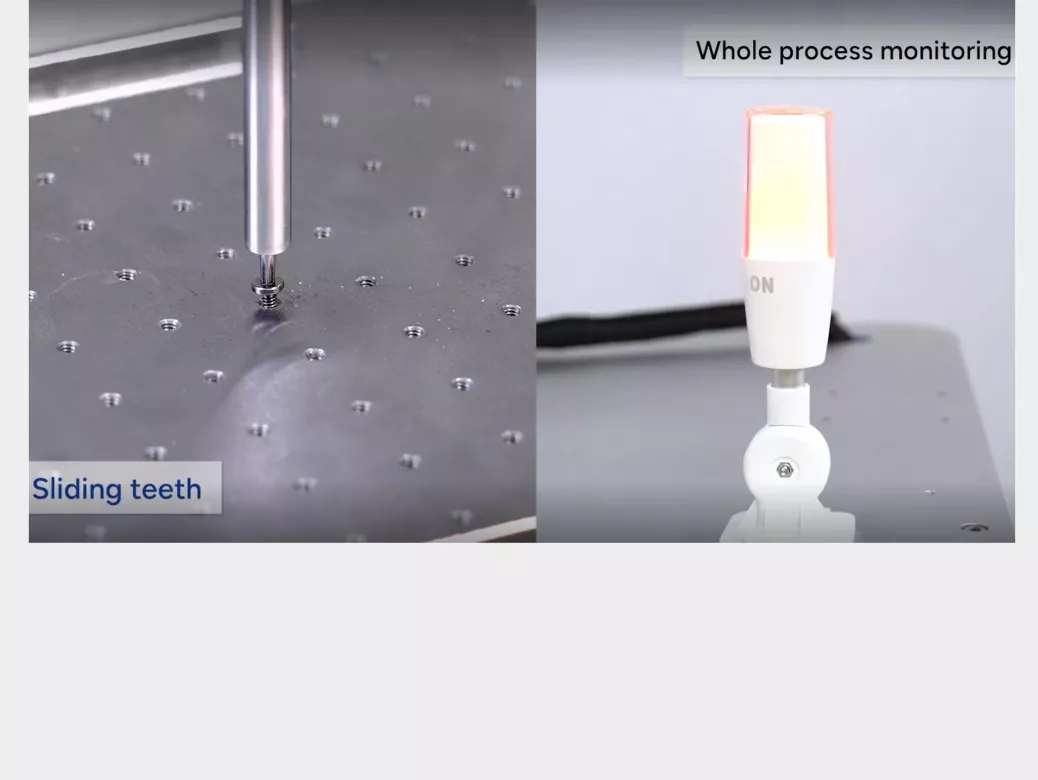

Superb screwdriving consistency

The Robotic solution and its dedicated software ensure precise screwdriver performance while tracking torque, angle, and height parameters from the pre-screwing to the final position.

Process control

Any quality issue is automatically detected by the equipment, and an alert is sent to indicate that human intervention is required before the system can resume normal operation.

Screwing flexibility

The solution can pick, place, and fast screws of any size, ranging from M1 to M10. Any screwing angle possible, depending on the needs of the part assembly. The quick tool changeover allows simple redeployment of the system for multiple part numbers.

Improve production speed

Automated screwdriving solution with a 2.5s cycle time removes production bottleneck and increases throughput of the entire line.

Extensions

Get a consultation

Feel free to contact us. We really like to communicate with our clients